MIG welding wire C25 refers to a 75% Argon and 25% Carbon Dioxide gas mixture, while C100 stands for 100% Carbon Dioxide. C25 generally provides better weld quality with less spatter, whereas C100 is more cost-effective but can result in rougher welds.

Selecting the right shielding gas for MIG welding is pivotal in achieving optimal weld performance and quality. C25 and C100 are two common gas choices used by professionals and hobbyists alike. Each mixture has its distinct advantages depending on the welding conditions and desired finish.

The C25 mixture is appreciated for its ability to produce cleaner welds with minimal spatter, making post-weld cleanup less labor-intensive. This makes C25 an excellent choice for welders who prioritize the aesthetics of their welds and work with thin to medium-thickness materials. On the other hand, C100 is often chosen for its cost-effectiveness, especially for thicker materials where weld appearance is not the primary concern. Users must weigh the pros and cons of each gas based on their specific welding needs to ensure the right balance between quality and cost efficiency.

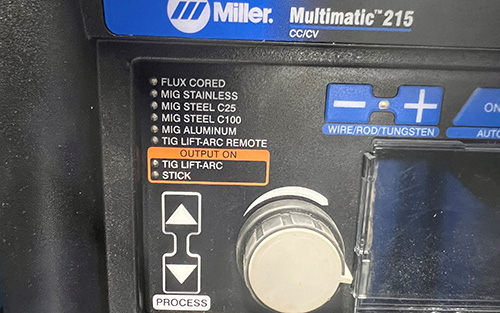

Credit: www.youtube.com

1. What Is Mig Steel?

MIG steel is a key material in welding. MIG stands for Metal Inert Gas. It is also known as Gas Metal Arc Welding (GMAW). Welders use MIG to join thin metal sheets together. This process involves an electric arc. This arc forms between a wire electrode and the metal workpiece. Heat is generated and metals fuse together.

1.1 Introduction To Mig Steel

MIG steel is popular in many industries. Think of automotive repair or creating metal structures. Here’s why it’s loved:

- Easy to learn: MIG welding is beginner-friendly.

- Fast: It is faster than other methods like TIG welding.

- Clean: It causes less splatter.

- Versatile: It can be used on various metals.

You can buy MIG steel in many forms. Common forms are spools or coils. The size and alloy depend on the job.

1.2 Types Of Mig Steel

Two main types of MIG steel are C25 and C100.

| Type | Description |

|---|---|

| C25 | Contains 25% CO2 and 75% argon. It is great for clean welds. It causes less spatter. |

| C100 | Pure CO2. It is cheaper. But it makes more spatter. Suitable for thicker metals. |

Choose C25 or C100 based on your welding needs. C25 gives cleaner results. C100 is cost-effective for heavy-duty work.

Credit: www.ebay.com

2. Understanding C25

Welcome to the comprehensive world of MIG welding, where selecting the right gas mixture makes all the difference. This essential part of the process directly influences the quality of the weld. Today, we dig deep into a popular choice among welders: C25. Here’s everything you need to know about C25—a blend commonly used for its versatility and weld quality.

2.1 Definition Of C25

The “C” in C25 stands for Carbon Dioxide, and the “25” represents the percentage of CO2 in the mixture. This gas blend has 25% Carbon Dioxide and 75% Argon. It is a standard mix for MIG welding that strikes a balance between welding quality and cost.

2.2 Composition Of C25

| Gas | Percentage |

|---|---|

| Carbon Dioxide (CO2) | 25% |

| Argon (Ar) | 75% |

C25’s composition brings together the best of both gases. Argon provides smooth arc stability and reduced spatter. Carbon Dioxide gives deep penetration for thicker materials.

2.3 Uses Of C25 Mig Steel

- General steel fabrication for a clean finish

- Automotive repairs where precision matters

- Metal art that requires a delicate touch

- Construction for strong, reliable joints

The versatility of C25 MIG steel allows welders to use it across various applications. It is particularly famed for its balance between penetration and bead appearance.

3. Understanding C100

Exploring Mig Steel, particularly C100, offers a snapshot of advanced welding applications. This section dives into what C100 is, its chemical makeup, and how it serves the industrial world. Focusing on C100 mig steel provides an in-depth look at a specialized option for professionals.

3.1 Definition Of C100

C100 mig steel is a type of gas metal arc welding (GMAW) wire. This designation refers to a specific category of welding gas mix where the shielding gas is composed of 100% carbon dioxide. Unlike its C25 counterpart, which contains 25% carbon dioxide and 75% argon, C100 employs a single gas component.

3.2 Composition Of C100

The single-element shielding gas used in C100 welding wire influences the welding process. High levels of carbon dioxide result in deeper penetration of the weld, impacting welding results significantly:

- Deep weld penetration for thicker materials

- Increased spatter compared to mixed gases

- Potentially rougher weld surface dependent on technique

3.3 Uses Of C100 Mig Steel

C100 mig steel possesses characteristics suitable for certain applications:

- Construction projects involving heavy steel sections

- Fabrication work requiring deep weld joints

- Industrial environments where weld appearance is of less concern

Cost-effectiveness and efficiency in the right settings make C100 a go-to for specific welding tasks.

4. Comparing C25 And C100

When delving into steel gases like C25 and C100, it’s crucial to understand their key differences. These differences affect their use across various applications. Let’s explore how C25 and C100 stand up against each other in terms of strength, welding, and cost efficiency.

4.1 Strength And Durability

C25 and C100 present varied strength levels. C25 is a blend of 75% Argon and 25% Carbon Dioxide. It creates less heat, affecting its penetration capabilities. C100, on the other hand, is pure Carbon Dioxide. It generates more heat, offering deeper penetration for thicker materials. This can impact overall strength and longevity of the welds. See the comparison:

| Gas | Heat Output | Material Penetration |

|---|---|---|

| C25 | Lower | Shallow |

| C100 | Higher | Deep |

4.2 Welding Performance

Welding performance varies greatly between C25 and C100. C25 produces less spatter, resulting in cleaner welds and a smoother finish. It suits thin to medium-thick metals. On the flip side, C100 might cause more spatter but excels with thick material welds due to its deep penetration potential.

4.3 Cost Analysis

The cost factor is pivotal in choosing between C25 and C100. C25 typically costs more due to its Argon content. C100, being simply Carbon Dioxide, is easier on the pocket. Here’s a simplified cost breakdown in points:

- C25 – Higher upfront costs, less wasted material.

- C100 – More affordable, potential for increased spatter clean-up costs.

In summary, deciding between C25 and C100 involves assessing material thickness, desired weld quality, and budget constraints. Choose wisely based on the specific needs of your project.

5. Choosing The Right Mig Steel

Finding the perfect MIG steel for your welding projects is a crucial step. It can be the difference between a clean, strong join and a weak, unreliable one. We are going to look at MIG steel types C25 and C100. Let’s delve into the factors you must consider and the best applications for each type.

5.1 Factors To Consider

Selecting the right MIG steel involves assessing several key aspects:

- Material Compatibility: Match the MIG steel to your base metals.

- Welding Environment: Are you working indoors or outside?

- Shielding Gas Needs: Consider gas mixtures that suit your application.

- Thickness of Material: Thicker metals may require different steel types.

- Power Supply: Ensure your equipment can handle the steel grade.

5.2 Applications And Recommendations

Each type of MIG steel has ideal uses. Let’s compare the applications of C25 and C100.

| Type | Composition | Applications | Recommendations |

|---|---|---|---|

| C25 | 25% CO2, 75% Argon | General fabrication, auto repair | Best for thin to medium thickness metals |

| C100 | 100% CO2 | Heavy manufacturing, construction | Good for thicker, heavier sections |

For DIY projects and light repair work, C25 is your go-to. It provides a cleaner weld with less spatter. For more robust, industrial jobs, C100 offers deeper penetration on thick materials. Both have their place in a welder’s toolkit!

Credit: www.millerwelds.com

Frequently Asked Questions On Mig Steel C25 Vs C100

What Does Mig Steel C100 Mean?

MIG steel C100 refers to welding with 100% carbon dioxide as the shielding gas. This gas choice affects the weld’s properties, including penetration and spatter levels.

What Is Mig Steel C25?

MIG steel C25 refers to a welding gas mixture composed of 25% carbon dioxide and 75% argon, used in MIG welding for mild steel.

Can You Use 100 Argon To Mig Weld Steel?

Yes, you can use 100% argon to MIG weld steel, but it’s best suited for thin sheets. For thicker steel, a mix of argon and CO2 is more common.

Can You Mig Weld Stainless Steel With C25?

Yes, you can MIG weld stainless steel using C25 gas, a mixture of 75% argon and 25% carbon dioxide, but it may not provide the best corrosion resistance.

Conclusion

Selecting the right MiG steel grade is crucial for your project’s success. C25 offers easier handling with its lower carbon content, while C100 boasts superior strength and hardness. Ultimately, your choice depends on the specific requirements of your welding application.

Remember, a well-informed decision ensures optimal performance and longevity of your welds. Choose wisely to achieve the best results for your metalworking needs.