For a 30 amp 220V circuit, use 10 gauge wire. This size ensures safety and compliance with electrical codes.

Understanding the correct wire gauge for a 30 amp, 220-volt circuit is critical for both electrical safety and efficiency. Electrical projects often require a specific wire size to handle the current that a particular voltage will draw. The right wire gauge helps prevent overheating and potential fire hazards.

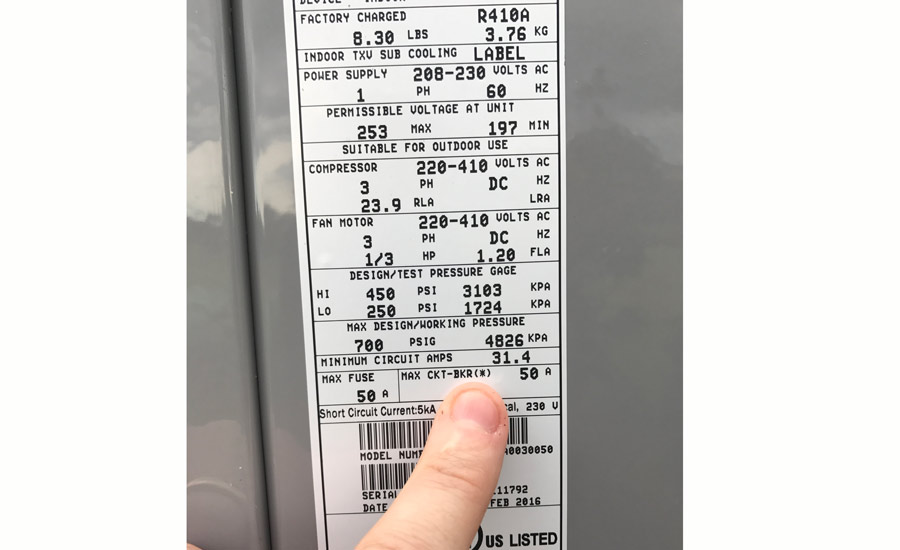

Wiring a home or a heavy-duty appliance such as an air conditioner, dryer, or an electric range requires the proper wire gauge to support the electrical load. Using 10 gauge wire for a 30 amp, 220-volt circuit aligns with the National Electrical Code recommendations, ensuring your installations meet legal safety standards while delivering the necessary power for high-demand appliances.

:max_bytes(150000):strip_icc()/installing-a-240-volt-circuit-breaker-1824649-hero-11c6b7fe534043a381b30d93bdd882a2.jpg)

Credit: www.thespruce.com

Importance Of Correct Wire Gauge

Choosing the right wire gauge for any electrical circuit is critical. This impacts not only the safety of the installation but also its efficiency. For a relatively high-powered circuit like a 30 Amp 220V setup, selecting the correct wire gauge is essential to prevent potential hazards and ensure optimal performance.

Preventing Overheating

The primary role of selecting the correct wire gauge is to prevent overheating. A wire that’s too thin for the electrical load can overheat. This situation can damage the insulation, melt wire sheathing, and potentially cause fires. Using at least a 10-gauge wire for a 30 Amp 220V circuit allows for a safe flow of electricity, limiting any risk of overheating.

Minimizing Voltage Drop

Minimizing voltage drop is crucial for the efficiency of electrical appliances. An undersized wire increases resistance in the circuit. This can cause a significant voltage drop, especially over longer runs. Appliances may then run less efficiently or sustain damage over time. A proper gauge wire like 10 AWG ensures minimal voltage drop, protecting appliance lifespan and conserving energy.

Credit: www.achrnews.com

Understanding Ampere And Voltage Ratings

Choosing the right wire gauge for a 30 amp, 220-volt circuit is important for safety and efficiency. Before selecting the wire, it’s essential to understand the fundamental concepts of ampere and voltage ratings. These two factors determine the electrical capacity and requirements of your wiring project. Getting these ratings right ensures a safe electrical system.

Defining Ampere

An ampere, commonly known as an amp, measures the electric current flow. For a 30 amp circuit, the wire must handle 30 units of electrical current safely. The wire gauge is crucial as it must carry the current without overheating. A standard for this is set by the American Wire Gauge (AWG) system. The correct wire gauge ensures that electrical currents travel efficiently and safely.

Explaining Voltage

Voltage measures the force that pushes electrical currents through wires. A 220V rating indicates a higher voltage level, which requires wires that can handle the increased pressure of electricity. Choosing the correct wire size for 220 volts ensures that the electrical system operates within its intended capacity, without risk of damage or hazard.

To summarize, for a 30 amp 220-volt circuit, you will typically need a 10-gauge wire. Selecting the appropriate wire size is not just a good practice but a necessity for the integrity and safety of your electrical system. Always adhere to local codes and standards when performing electrical work.

Determining The Correct Wire Gauge

Embarking on an electrical project requires knowing the right materials for a safe and efficient setup. Choosing the correct wire gauge for a 30 amp, 220-volt circuit is essential. This selection ensures that electrical systems function properly without risks of overheating or damage.

Considering Amperage

To begin with, the amperage, or current capacity, of a circuit dictates the minimum wire gauge needed. A 30 amp circuit requires a wire that can handle the continuous flow of electricity without overheating. The National Electrical Code (NEC) provides guidelines:

- No. 10 gauge for copper wiring

- No. 8 gauge for aluminum or copper-clad aluminum wiring

Understanding Voltage Drop

Voltage drop becomes an issue in long runs of wire. Here, electrical resistance leads to a reduction in voltage. To combat this:

- Distance of the run must be measured accurately

- Determine if a wire gauge larger than the minimum requirement is necessary

A wire gauge calculator or chart can help decide if an upsize is needed for your specific distance.

Consulting National Electrical Code (nec)

It’s crucial to consult the NEC for the latest standards. The NEC table outlines:

| Ampacity | Copper Wire Gauge | Aluminum Wire Gauge |

|---|---|---|

| 30 Amps | 10 | 8 |

Following these guidelines ensures that the chosen wire gauge will sufficiently support a 30 amp, 220V circuit.

Credit: www.amazon.com

Wire Gauge Options For 30 Amp 220v

Choosing the appropriate wire gauge for a 30 Amp 220V circuit is vital. The right size ensures safety and efficiency. Let’s look at the options.

10-gauge Wire

10-gauge wire is commonly used for 30 Amp 220V circuits. This wire size is suited for moderate lengths and typical loads. It is the minimum requirement for such setups. Its capacity handles household appliances well, ensuring smooth operation.

8-gauge Wire

For longer runs or heavier loads, 8-gauge wire offers more headroom. This thicker wire reduces voltage drop over distance. It handles up to 40 amps, providing a safety margin for your 30 Amp 220V circuit.

6-gauge Wire

6-gauge wire comes into play for industrial settings or where high-powered equipment is in use. It carries up to 55 amps, making it ideal for distances up to 100 feet. This wire ensures your 30 Amp appliances run without hiccups even over extensive lengths.

| Wire Gauge | Amps | Recommended Use |

|---|---|---|

| 10-Gauge | 30 Amps | Standard household appliances |

| 8-Gauge | 40 Amps | Longer runs, safety margin |

| 6-Gauge | 55 Amps | Industrial equipment, extensive lengths |

“` This structured HTML block provides an easy to comprehend breakdown of wire gauge options for 30 Amp 220V circuits, tailored for an engaging blog post. The included table serves as a quick reference, summarizing the content for readers.

Factors To Consider When Choosing Wire Gauge

Finding the right wire gauge for a 30 Amp 220V circuit is essential for safety and efficiency. Certain factors play a crucial role in this decision. The wire must handle the current without overheating, which could lead to insulation damage or even fire. Let’s look at what to consider when selecting the appropriate wire gauge.

Length Of The Wire Run

The distance the electricity travels through the wire affects its capacity. A longer run has higher resistance, which may require a thicker wire to safely carry the current. Follow these steps:

- Measure the distance from the power source to the appliance.

- Determine if extra thickness is needed to prevent voltage drop.

- Ensure the wire size selected compensates for any length-related losses.

Type Of Appliance

The appliance’s specific demands influence the wire size. Here’s what to keep in mind:

| Appliance Characteristics | Wire Gauge Implications |

|---|---|

| Continuous Load | Select a gauge that allows for constant current without overheating. |

| Surge Demands | Consider thicker wires to handle potential surges safely. |

| Manufacturer’s Recommendation | Always check the appliance manual for specific wire gauge requirements. |

Not all appliances consume power equally. Some might only need a 30 Amp wire occasionally, while others require it continuously. Regular surges can significantly influence your choice.

Installation Considerations

When installing a 30 Amp 220V wire, it’s critical to get the details right. Several technical choices must align with electrical codes. Safety, effectiveness, and compliance are the top priorities. Two key aspects include setting up a dedicated circuit and selecting the right wire material.

Using A Dedicated Circuit

A dedicated circuit is essential for a 30 Amp 220V application. It means this circuit is solely for one purpose. No other appliances will share this power. It prevents overload and tripping breakers. Always follow these steps:

- Check the electrical panel to ensure there is space for a new circuit.

- Install a 30 Amp double-pole breaker firmly connected to the panel.

- Label the circuit clearly. This helps with future maintenance.

Choosing The Right Wire Material

Selecting the correct wire material is crucial for safety and performance. Copper and aluminum are common choices. Here are the recommendations:

| Material | Attributes | Usage |

|---|---|---|

| Copper | Durable, less expansion, better conductivity | Ideal for 30 Amp circuits |

| Aluminum | Cost-effective, more expansion, less conductivity | Requires larger gauge for safety |

Choose copper for its reliability and efficiency. If aluminum is used, anticipate a larger gauge due to its lower conductivity. Always adhere to local electrical codes. They might have specific requirements for wire materials. Consult a professional electrician for a perfect installation.

Potential Risks Of Using Incorrect Wire Gauge

Choosing the right wire gauge for a 30 amp 220V circuit is critical. Incorrect wire size can lead to serious issues. Understanding risks helps prevent accidents. We reveal the dangers of an incorrect wire choice below.

Fire Hazards

Wires that are too thin for a 30 amp 220V circuit can overheat. Overheating causes insulation to melt. Exposed wires create fire risks. They can ignite nearby materials. A fire can damage property and risk lives.

Damage To Appliances

Incorrect gauge wires affect appliance performance. Low gauge wires cause voltage drops. Appliances may receive insufficient power. Inefficient operation and potential damage follow. Lifespans of devices are shortened due to stress.

Identifying the Correct Wire Gauge

- Check appliance manuals for gauge requirements.

- Use 10-gauge wire for 30 amp circuits.

- Consult a professional electrician for confirmation.

Common Mistakes And How To Avoid Them

When setting up electrical systems, choosing the correct wire gauge for 30 Amp 220V circuits is crucial. Homeowners and electricians sometimes make errors that can lead to safety hazards or malfunctioning equipment. Identifying these common mistakes and understanding how to avoid them is the first step toward a safe and efficient installation.

Underestimating Wire Gauge

Using the wrong wire gauge is a frequent oversight. The right wire gauge ensures that electrical systems function correctly and safely. For a 30 Amp 220V circuit, the minimum recommended size is 10 AWG.

Here’s how to avoid this mistake:

- Always refer to the National Electrical Code (NEC) for guidelines.

- Check the amperage and voltage requirements.

- Use a wire gauge calculator when uncertain.

Ignoring Voltage Drop

A voltage drop occurs when the electrical current travels over long distances, reducing the voltage that reaches the destination. This can affect the performance of your appliances. Use thicker wires if the cable will run a long distance.

Avoid this common pitfall:

- Calculate the voltage drop before installation.

- Consider using a larger gauge wire for long runs.

- Adhere to NEC standards on maximum voltage drop (usually 3%).

Professional Help Vs. Diy

Deciding between professional help or going the DIY route for wiring can be tough. When working with a 30 Amp 220V circuit, safety is paramount. Both options have their benefits. Let’s explore what’s best for your home and skill level.

!– Benefits Of Consulting An Electrician —

- Expertise: Electricians have the training to handle complex electrical tasks.

- Gauge Knowledge: They know the best gauge wire for a 30 Amp 220V circuit.

- Safety: They follow codes to ensure all work is safe and up to standard.

- Insurance: Hiring a pro can help with insurance coverage in case of issues.

- Peace of Mind: You rest easy knowing the job is done right.

!– Do-it-yourself Tips —

If you opt to DIY, important things need your attention. Below are tips to guide you.

- Learn: Research your local electrical codes and regulations.

- Plan: Have a clear wiring diagram before you start.

- Tools: Ensure you have the right tools for the job.

- Safety: Turn off power before you begin work.

- Check: Use a wire gauge chart to confirm you have the correct size.

Remember, 10-gauge wire is typically recommended for a 30 Amp 220V circuit. Yet, other factors may influence this. Consult a chart or a professional for accuracy.

Frequently Asked Questions Of What Gauge Wire For 30 Amp 220v

What Is The Recommended Wire Gauge For 30 Amp 220v?

For a 30 Amp 220V circuit, the recommended wire gauge is 10 AWG. This thickness ensures safe operation and reduces the risk of overheating or electrical fires. Always follow local electrical codes.

Can I Use 12 Awg Wire For 30 Amp 220v Circuits?

No, 12 AWG wire is not suitable for 30 Amp 220V circuits; it’s too thin. Using a wire gauge that’s too small can lead to overheating and potential hazards. Stick with 10 AWG for safety.

What’s The Maximum Length For 10 Awg Wire On A 30 Amp Circuit?

The maximum length depends on the voltage drop you can tolerate. For a 30 Amp, 220V circuit, a 10 AWG wire can run up to 150 feet with minimal voltage drop. Keep runs short for optimal performance.

Is Stranded Or Solid Wire Better For 30 Amp 220v Circuits?

Stranded wire is often preferred for 30 Amp 220V circuits due to its flexibility and reduced risk of breakage. However, both stranded and solid wires, if 10 AWG, are generally suitable for such installations.

Conclusion

Selecting the correct wire gauge for your 30 amp 220V needs is crucial for safety and efficiency. It is clear that a 10-gauge wire is typically the best choice. This ensures proper current flow without overheating risks. Always prioritize electrical codes and consult with professionals for optimal results.

Equipped with the right information, you can make informed decisions for your wiring projects.