6011 welding rods are versatile electrodes used primarily for welding through rusty, dirty, or painted surfaces. They cater to welding jobs that involve quick, on-site repairs and fabrication.

6011 welding rods possess a deep penetrating arc, making them optimal for tackling tough-to-penetrate surfaces in the construction, shipbuilding, and repair industries. Designed for use with AC and DC power supplies, these rods feature a high cellulose potassium-type coating that enables their suitability for both experienced welders and beginners.

The flexibility of 6011 rods means they perform exceptionally well on various metals, including mild steel, facilitating strong and durable welds in multiple positions such as vertical, overhead, and horizontal. Their ease of use and effectiveness in challenging conditions have made 6011 welding rods an essential item for welders facing diverse and demanding environments.

Composition

Understanding the composition of 6011 welding rods is crucial for welders. These rods have unique elements that make them highly versatile. They are perfect for various welding jobs. Let’s delve into what makes up these powerful tools.

Chemical Makeup

The 6011 welding rod is known for its robust and flexible welding capabilities. Its core wire is designed to facilitate deep penetration into metals. This wire is made from a high-quality, durable steel alloy. The alloy typically contains:

- Carbon

- Manganese

- Silicon

These elements are critical. They ensure the rod can withstand various welding conditions. They also ensure strong joins.

Coating Materials

On the outside, 6011 rods have a special coating. This coating is made up of several materials:

| Coating Component | Function |

|---|---|

| Cellulose | Produces a gas shield during welding |

| Minerals | Stabilizes the arc |

| Potassium | Enhances ion exchange for arc stability |

The coating also contains binders and fillers. This unique mix gives the rod its deep penetration quality. It also helps create a smooth, easy-to-clean slag.

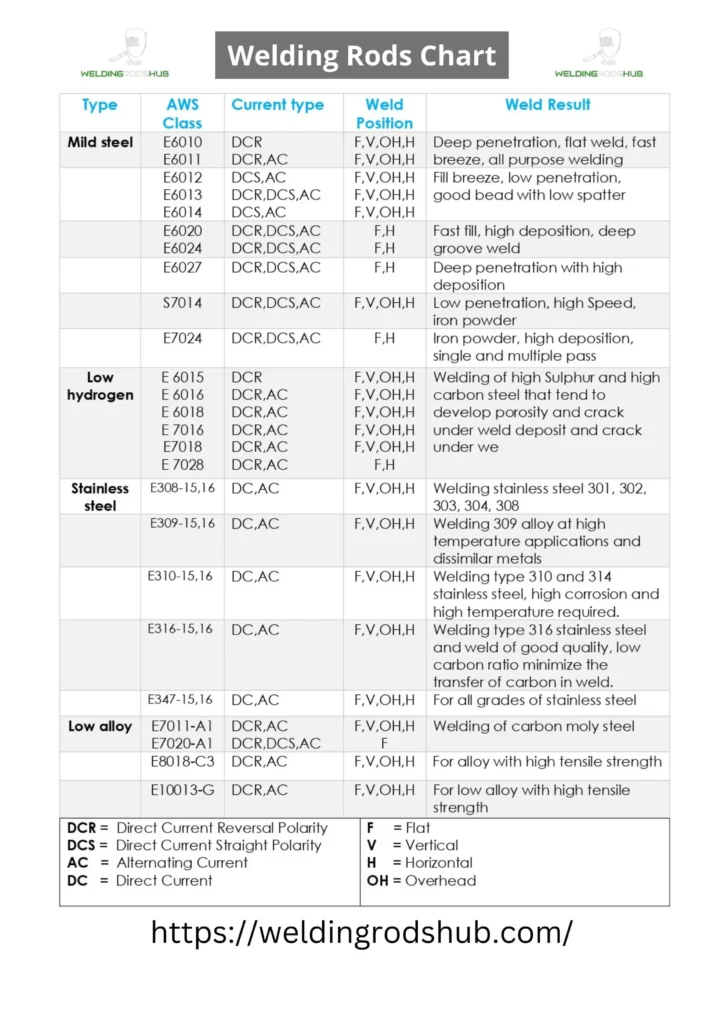

Credit: weldingrodshub.com

Welding Applications

Understanding the function of 6011 welding rods is essential for professionals in metal work. These rods are versatile tools. They join metals firmly. Let’s look at the applications for these handy rods.

General Purpose Welding

6011 welding rods shine in their adaptability. These rods are a first-choice for repair work. They handle different welding positions easily. You can use them on dirty or rusty metals too. This makes them highly resourceful for quick fixes or under imperfect conditions.

- Repairing farm equipment

- Fixing vehicles

- Building or repairing ships

Ideal Metal Thickness For 6011 Rods

The 6011 welding rods are suitable for thin and medium gauge metals. They work well from 4mm to 12mm thickness. Their design allows deep penetration. They create strong welds on various metal sizes.

| Metal Thickness (mm) | Use 6011 Rod? |

|---|---|

| Less than 4mm | Not Ideal |

| 4mm to 12mm | Yes |

| More than 12mm | Possible, not optimal |

Choose the right rod for the job. For thin materials, 6011 rods are a reliable choice. They make sure the task gets done effectively and efficiently.

Welding Techniques

Mastering the use of 6011 welding rods means understanding two critical aspects: the right amperage settings and how to handle the electrode. Users appreciate these rods for their versatility, especially in repair work and construction where different materials and positions are involved. Read on to grasp how these techniques can significantly boost welding efficiency and results.

Optimal Amperage Settings

Choosing the correct amperage is crucial for creating strong, deep welds without causing damage. The amperage setting varies based on the rod size and the thickness of the metal. Below is a guide to help set your welder:

| Rod Diameter | Minimum Amperage | Maximum Amperage |

|---|---|---|

| 3/32 inch | 40 | 85 |

| 1/8 inch | 75 | 125 |

| 5/32 inch | 110 | 165 |

Start with a lower setting to avoid burn-through, especially on thinner metals. Slowly increase the amperage until the arc is stable and smooth.

Proper Electrode Manipulation

Welding with the 6011 rods requires skillful handling. The right technique ensures deep penetration and a clean, slag-free weld. Here’s what to remember:

- Strike the arc like striking a match.

- Keep a short arc length; too long will create spatter.

- “Whip and pause” technique helps manage heat on thin metals.

- For thicker metals, use a steady, dragging motion.

Constant practice will improve your skill to manipulate the electrode efficiently. This will result in solid welds on a variety of projects using 6011 rods.

Credit: askforney.com

Advantages

6011 welding rods stand out in the welding industry for their versatility and ease of use. These electrodes facilitate effective welding in a variety of settings, providing solutions for complex and everyday welding tasks. Below, we discuss the unique advantages that make 6011 welding rods widely popular among professionals and DIY enthusiasts alike.

High Penetration Capability

The 6011 welding rods boast a high penetration capability. This quality is critical when dealing with thick materials or creating deep welds. The deep penetration also ensures strong welds, crucial for the integrity and longevity of the welded structure.

Suitable For Rusty Or Dirty Materials

Unlike other welding rods, 6011 rods have the remarkable ability to weld through rusty or dirty materials. This asset minimizes preparation time as there’s less need for the thorough cleaning of metal surfaces prior to welding, making them highly practical for urgent repairs or when working with used materials.

Limitations

While 6011 welding rods are versatile, they are not perfect for every job. It’s crucial to understand where these rods fall short. This ensures the best results for your welding projects. Below, explore some key limitations of the 6011 welding rods.

Not Suitable For Thin Metals

One of the major limitations of 6011 welding rods is their performance on thin metals. Their intense penetration can cause burn-through, especially if the metal is too thin. Here are a few points to consider:

- Risk of warping: The high heat can easily warp thin materials.

- Rod size matters: Smaller rod sizes might reduce this risk.

- Material thickness: These rods work best on metals thicker than 1/16 inches.

Low Aesthetic Appeal

The 6011 welding rods offer less aesthetic appeal in their finishes. Smoothness and appearance often fall short when compared to other rods. Look at these considerations:

| Welding Rod Type | Aesthetic Finish |

|---|---|

| 6011 | Rougher finish, requires clean-up |

| Others (e.g., 7018) | Smooth, often more appealing finish |

- Spatter level: Higher spatter compared to other rods means more post-weld cleaning.

- Slag removal: Slag must be chipped away, which can affect the final look.

- Skill level: A skilled welder can improve appearance, but these rods generally lag behind others in finish.

Storage And Handling

Storage and handling of 6011 welding rods ensure their optimal performance and maintain safety. It’s important to understand how to properly store and handle these rods. This will maximize their lifespan and maintain quality in every weld. Let’s dive into the specifics.

Proper Storage Conditions

Creating the right environment for your welding rods is crucial.

- Keep rods dry to prevent moisture absorption.

- Store them in a cool and dry place.

- Avoid places with temperature fluctuations.

- Use original packaging or a sealed container.

- Label storage areas to avoid misplacement.

Precautions For Handling 6011 Rods

Handling these rods with care is vital. Here’s what to keep in mind:

- Wear protective gloves to handle rods.

- Do not touch the rod tip to prevent oil transfer.

- Avoid dropping rods as they might crack.

- Open containers only when needed.

- Use rods one at a time to reduce exposure.

Safety Considerations

When working with 6011 welding rods, safety is a priority. These versatile rods, used for a variety of welding tasks, produce intense heat and bright light. Such conditions necessitate stringent safety measures to protect welders from harm. Understanding and adhering to these measures ensures a safe work environment and prevents accidents.

Protective Gear Requirements

Proper protective gear is essential for any welder using 6011 rods. Key items include:

- Welding helmet: Shields eyes from harmful rays.

- Fire-resistant clothing: Prevents burns from sparks.

- Gloves: Protects hands from heat and electric shock.

- Boots: Guards feet against falling debris.

- Ear protection: Reduces noise-induced hearing loss.

Wearing the right gear minimizes risks from the intense conditions of welding with 6011 rods.

Ventilation Needs During Welding

Adequate ventilation is critical in preventing harmful fume inhalation. Key considerations include:

| Area | Ventilation Requirement |

|---|---|

| Indoor Spaces | Exhaust systems or fans to circulate air. |

| Confined Areas | Specialized ventilation or respiratory protection. |

| Outdoor Sites | Natural airflow; position work to windward side. |

Ensuring proper airflow reduces the risk of respiratory issues and maintains clear visibility during welding.

Credit: www.linkedin.com

Comparative Analysis

Welding is an art, and every artist needs the right tools. In our comparative analysis, we’ll delve into how 6011 welding rods stand out in the toolkit of welders. These rods are like Swiss Army knives due to their versatility and reliability. Whether tackling rusty materials or working on a tricky join, 6011 rods are often the go-to choice. Now, let’s compare them with their counterparts and explore their specific applications.

Comparison With Other Welding Rods

When it comes to joining metals, not all rods are created equal. The 6011 welding rods are unique. They feature a high cellulose sodium-type coating. This allows for deep penetration and a strong, sturdy weld. Their design is such that you can use them on AC and DC currents, unlike some other rods.

| Welding Rod | Tensile Strength | Current Type | Polarity | Penetration | Use Case |

|---|---|---|---|---|---|

| 6011 | 60,000 psi | AC/DC | Reverse | Deep | Dirty/Rusty Materials |

| 6013 | 60,000 psi | AC/DC | Reverse or Straight | Medium | General Fabrication |

| 7018 | 70,000 psi | AC/DC | Reverse or Straight | Low | Clean Materials, High Strength |

As seen, compared to 6013’s medium penetration and 7018’s low penetration, 6011 rods ensure a powerful strike through rust, paint, and dirt. This makes 6011 superior for challenging conditions.

Specific Use Cases For 6011 Rods

The versatility of 6011 welding rods shines across multiple applications. Below are their specific use cases:

- Repairs: Ideal for fixing farm equipment, where surfaces are often not pristine.

- Construction: A strong choice when constructing or repairing steel frameworks.

- Pipe Welding: Their deep penetration aids in joining pipes, even with rusty conditions.

- Shipbuilding: In marine environments, 6011’s ability to handle wet conditions proves essential.

These rods withstand varied climates and materials that would otherwise complicate the welding process. The robustness and adaptability of 6011 welding rods render them invaluable in settings where precision and strength are paramount.

Frequently Asked Questions For What Are 6011 Welding Rods Used For

What Is A 6011 Welding Rod?

A 6011 welding rod is a stick electrode commonly used in welding for its deep penetration and flexibility. It’s particularly useful for welding rusty or oily steel in maintenance or repair work.

Can 6011 Rods Be Used On Thin Metal?

Yes, 6011 rods can be used on thin metal. They offer a fast-freeze rod feature, making them suitable for welding thinner materials, though skill and control are required to prevent burn-through.

What Positions Can 6011 Welding Rods Be Used In?

6011 welding rods are versatile and can be used in all positions. They are designed to perform well in vertical, overhead, horizontal, and flat welding positions, ideal for various applications.

Are 6011 Rods Suitable For Beginner Welders?

6011 rods can be suitable for beginners due to their ease of striking and re-striking the arc, but they may require practice to manage penetration and prevent slag entrapment.

Conclusion

Wrapping up, 6011 welding rods are essential for tricky repairs and jobs requiring deep penetration. They’re versatile, handling various metals and positions with ease. Keep this rod in your toolkit for when strength and flexibility are paramount. Remember, skill grows with practice, so get those helmets on and start welding.