Choosing between stick welding or MIG welding depends on the job’s specifics; MIG welding is generally faster and easier, while stick welding is more versatile and works well outdoors. Both stick welding and MIG welding have their distinct advantages, making them suitable for different types of welding tasks.

Stick welding, officially known as Shielded Metal Arc Welding (SMAW), is a process that excels in outdoor conditions and on rusted or dirty metals. It requires less equipment, making it more portable and cost-effective for small repairs or construction projects.

On the other hand, MIG welding, or Gas Metal Arc Welding (GMAW), is often favored in industrial settings for its speed, ease of use, and the high-quality welds it produces, especially on thin metals. Your choice should align with the project’s requirements, including location, material type, and desired precision. Expert welders consider the welding application, accessibility to power sources, and metal thickness when deciding between these two methods.

Credit: weldguru.com

Comparison Of Stick Welding And Mig Welding

When deciding between stick welding and MIG welding, it is important to know the differences. Each type has advantages for certain jobs. This section dives into how they compare, helping you choose the right method.

Welding Process

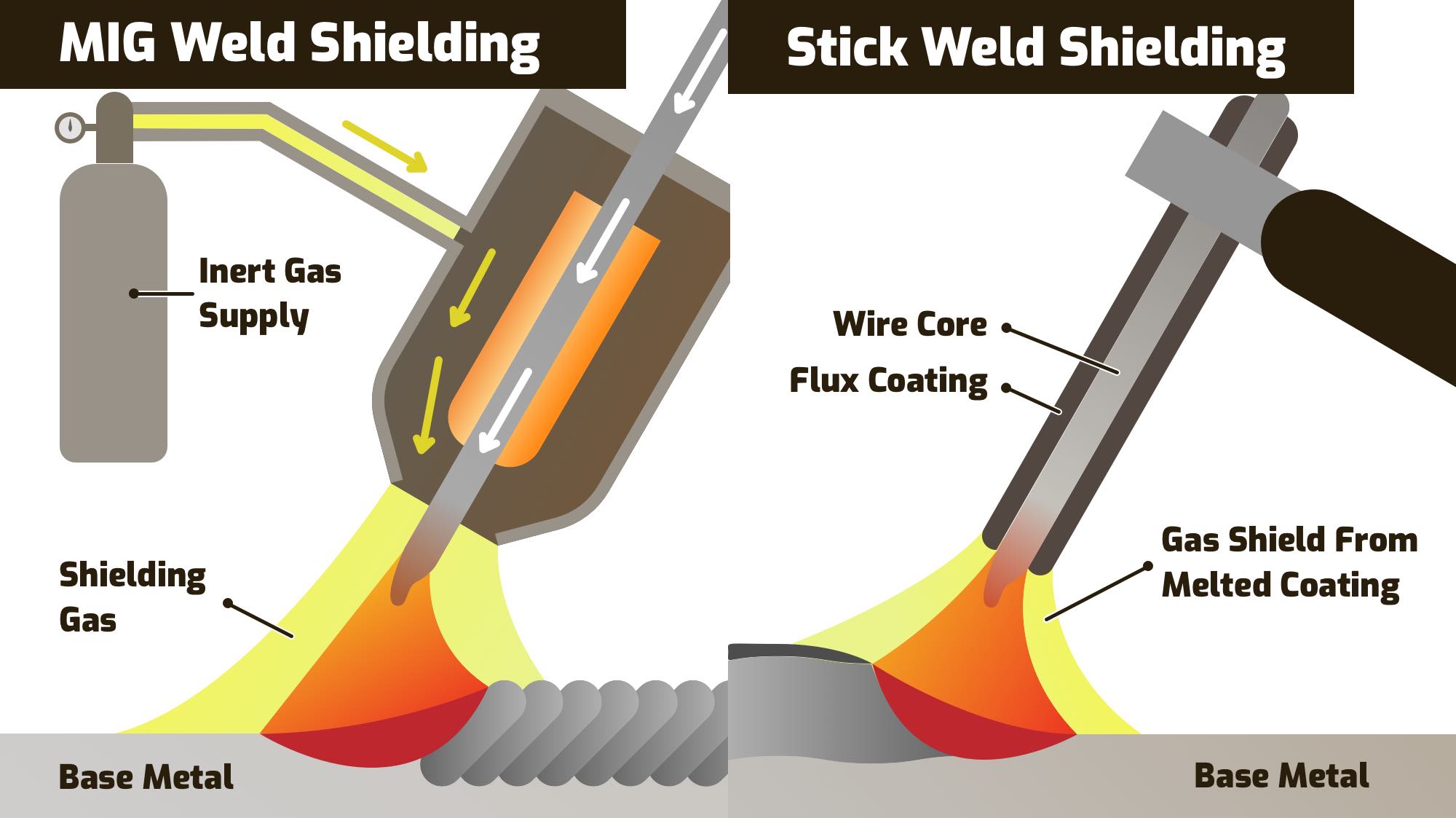

Stick welding, also known as Shielded Metal Arc Welding (SMAW), uses an electrode. This electrode melts to form the weld. It works outdoors, even in the wind or rain. MIG welding, or Metal Inert Gas Welding, uses a wire that continuously feeds through a gun. This creates a weld pool. It is fast and efficient for indoors.

Suitability For Different Materials

- Stick welding is versatile. It works well on iron, steel, and most alloys.

- MIG welding is also versatile. It can weld various materials including mild steel, aluminum, and stainless steel.

Skill Level Required

Stick welding requires more skill. The welder must control the electrode. MIG welding is easier to learn. The process is semi-automated. It is great for beginners.

Credit: weldguru.com

Advantages And Disadvantages

Choosing between stick welding and MIG welding involves weighing their pros and cons. Let’s explore these to make an informed decision on which technique suits your needs best.

Advantages Of Stick Welding

- Versatility: Works well on dirty or rusty metals.

- Portability: Requires no gas, easy to use outdoors.

- Durable Welds: Ideal for heavy-duty jobs.

Disadvantages Of Stick Welding

- Steep Learning Curve: Requires more skill to master.

- Slower Process: Not as efficient as other methods.

- Higher Clean-up: Leaves slag that needs removal.

Advantages Of Mig Welding

- Ease of Use: Great for beginners.

- Speed: Faster than stick welding. More efficient.

- Clean Results: Less clean-up needed post-weld.

Disadvantages Of Mig Welding

- Cost: Generally more expensive to start.

- Gas Requirement: Needs shielding gas. Not great for windy areas.

- Sensitivity: Not ideal for rusty or dirty metal.

Cost And Equipment

When choosing between stick welding and MIG welding, the cost of equipment often plays a crucial role. Both methods come with unique equipment needs which can influence your decision based on your budget and the value you seek.

Equipment For Stick Welding

Stick welding, also known as Shielded Metal Arc Welding (SMAW), requires less complex equipment. The essentials for stick welding include:

- Welding machine: This is the power source for creating the electric arc.

- Electrode holder and electrodes: The stick that melts to form the weld.

- Ground clamp: Completes the electrical circuit on the workpiece.

- Welding cables: Connect the machine to the holder and ground clamp.

- Personal protective equipment: Includes a helmet, gloves, and safety glasses.

Cost Comparison

Initial setup cost for stick welding tends to be lower compared to MIG welding. The table below summarizes the costs for both setups:

| Item | Stick Welding | MIG Welding |

|---|---|---|

| Welding Machine | $100 – $500 | $500 – $2000 |

| Accessories & Consumables | $50 – $100 | $100 – $200 |

| Protective Gear | $50 – $150 | $50 – $150 |

| Total Initial Cost | $200 – $750 | $650 – $2350 |

Operating costs also differ, with stick welding typically having fewer expenses in the long run.

Equipment For Mig Welding

MIG welding, or Gas Metal Arc Welding (GMAW), requires more advanced equipment. A MIG setup includes:

- MIG welding machine: Typically more expensive due to precise control features.

- Wire feed system: Feeds the welding wire from the spool.

- Welding gun and wire: The gun controls the wire and shielding gas.

- Shielding gas and tanks: Protects the weld from contamination.

- Ground clamp and cables: Similar to stick welding for establishing contact.

- Personal protective equipment: Same requirements as stick welding for safety.

Credit: www.quora.com

Applications And Conclusion

Deciding whether stick welding or MIG welding is better requires understanding their unique applications. Each method offers advantages for different scenarios. Let’s explore the common uses for both techniques.

Common Applications For Stick Welding

- Construction projects: Ideal for heavy-duty jobs like building structures.

- Outdoor repairs: Works well even in windy conditions.

- Industrial maintenance: Suitable for fixing equipment and machinery.

- Thick materials: Can join metals with high thickness effortlessly.

Common Applications For Mig Welding

- Automotive repair: A go-to for fixing car parts due to clean welds.

- Robotics: Ensures precise and homogeneous welds in automated processes.

- Home projects: User-friendly option for DIY enthusiasts.

- Thin materials: Excels at joining metals with low thickness.

Conclusion

Stick welding shines in robust, outdoor, or industrial settings where versatility and wind resistance are key. MIG welding reigns in precision tasks and when working with thinner materials. The best method depends on project demands and environmental conditions. Insight into each technique’s applications ensures the right choice for optimal results.

Frequently Asked Questions Of Which Is Better Stick Welding Or Mig

What Is The Key Difference Between Stick And Mig Welding?

Stick welding, or SMAW, uses an electrode that doubles as filler material, creating a weld with an electric arc. MIG welding, or GMAW, feeds a wire electrode through a gun, providing a continuous weld with a shielding gas.

Which Welding Method Is Easier For Beginners?

MIG welding is generally considered easier for beginners. It offers a more straightforward setup, cleaner welds, and requires less skill to produce consistent results compared to Stick welding.

Can Stick Welding Be Used Outdoors Effectively?

Yes, Stick welding is especially effective outdoors. Its versatility allows it to perform well in windy conditions where MIG welding might struggle without adequate shielding gas coverage.

Which Welding Type Is More Cost-effective?

Stick welding tends to be more cost-effective due to the simplicity of the equipment and the absence of gas. However, for large scale or continuous welding, MIG might be more efficient and could reduce overall costs.

Conclusion

Deciding between stick welding and MIG welding boils down to your project requirements. Both methods have their unique advantages and best-use scenarios. For heavy-duty repairs or outdoor conditions, stick welding shines. MIG welding excels with thinner materials and indoor tasks.

Choose the one that aligns with your needs for a successful weld.